Innovative solution for the reliable joining of aluminum strands and copper sleeves with resistance welding from STRUNK Connect.

While resistance welding has been used successfully for copper-copper connections in the automotive wiring system for decades, joining aluminum and copper in the wiring harness was previously considered a difficult connection. This was due to the aluminum oxide on each individual strand of the cables and on the surface of BUSBARS. The challenge was to break this and then avoid uncontrolled melting of the aluminum in order to achieve an optimum connection in terms of conductivity (contact resistance) and mechanical and long-term stability. For this purpose, intermetallic phases and brittleness must be avoided.

NEWS:

STRUNK Connect has successfully created an aluminum-copper connection with extremely high durability and minimal contact resistance. This can now be used in various areas of vehicle electrical systems and high-voltage applications:

- Aluminium BUSBAR systems with copper connectors or FLEX-BUSBARS to make the rail systems more flexible

- Aluminum cables (also in very high cross-section range) to copper contacts or HV contacts in sleeve form

Cu connections for aluminum BUSBARS – S2R process:

Due to cost and weight savings, aluminum is increasingly being used for busbar networking in the vehicle electrical system. Long paths, such as the loading path, are particularly affected by this. For these applications, STRUNK CONNECT offers a butt welding process that reliably connects very precise copper screw-on pieces (terminals) to the ends of the aluminum BUSBARS.

The advantage of butt welding here is the space-saving contacting, especially for busbars that have to be laid tightly, as is the case in the charging path at the socket. In addition to the space savings, the very low contact resistance (a few µOhm) combined with a convincing holding force (depending on cross-section and material) of approx. 10,000N for 100mm² aluminum BUSBAR should be mentioned. Furthermore, there are also material savings compared to lap welding, which lead to further cost reductions.

Special structural elements multiply the resulting contact surface significantly, generating these high holding forces and virtually no contact resistance. The connection is made without additional materials such as solder or similar. The process breaks the oxide layer using a special, very fast STRUNK control system, among other things, so that the materials are joined with long-term stability and without aluminum spraying. This welding process for BUSBARS is also possible with CU strands or CU braid strands to make the conductor rail sets more flexible.

Aluminum stranded wire connections to (HV) round contacts – STRUNK HC-L process:

STRUNK CONNECT has developed a new process to reliably connect aluminum cables to round contacts using resistance welding.

- the metallic connection to the round contact (interior)

as well as - the metallic connection of the individual strands (cores) to each other

makes it possible. The cable lugs or round contacts are coated to prevent intermetallic phases and achieve long-term stability. Specially adapted resistance welding machines and the associated “ALUMINIUM” application software are now available from STRUNK Connect, which together enable a controllable and stable welding process between the strands and the necessary connection to the contact is achieved via a brazed joint of the respective coating.

This connection is also characterized by high retention forces and excellent conductivity from the aluminium cable to the copper contact. The breaking up of the oxides and the exact melting temperature of the strands is achieved by a special application of the STRUNK WELDING CURRENT CONTROL.

STRUNK HC-L process – properties and advantages

- Cross-sections: up to 160 mm²

- Stable connection of the strands to each other and between strands and sleeve material

-

Fig.1: Very good connection between the strands

- Highly resilient with very good mechanical properties

- While resistance welding has been used successfully for copper-copper connections in the automotive wiring system for decades, joining aluminum and copper in the wiring harness was previously considered a difficult connection. This was due to the aluminum oxide on each individual strand of the cables and on the surface of BUSBARS. The challenge was to break this and then avoid uncontrolled melting of the aluminum in order to achieve an optimum connection in terms of conductivity (contact resistance) and mechanical and long-term stability. For this purpose, intermetallic phases and brittleness must be avoided.

NEWS:

STRUNK Connect has successfully created an aluminum-copper connection with extremely high durability and minimal contact resistance. This can now be used in various areas of vehicle electrical systems and high-voltage applications:- Aluminium BUSBAR systems with copper connectors or FLEX-BUSBARS to make the rail systems more flexible

- Aluminum cables (also in very high cross-section range) to copper contacts or HV contacts in sleeve form

Cu connections for aluminum BUSBARS – S2R process:

Due to cost and weight savings, aluminum is increasingly being used for busbar networking in the vehicle electrical system. Long paths, such as the loading path, are particularly affected by this. For these applications, STRUNK CONNECT offers a butt welding process that reliably connects very precise copper screw-on pieces (terminals) to the ends of the aluminum BUSBARS.

The advantage of butt welding here is the space-saving contacting, especially with busbars that have to be laid tightly, as is the case in the charging path at the socket. In addition to the space savings, the very low contact resistance (a few µOhm) combined with a convincing holding force (depending on cross-section and material) of approx. 10,000N for 100mm² aluminum BUSBAR should be mentioned. Furthermore, there are also material savings compared to overlap welding, which lead to further cost reductions.

Special structural elements multiply the resulting contact surface significantly, generating these high holding forces and virtually no contact resistance. The connection is made without additional materials such as solder or similar. The process breaks the oxide layer using a special, very fast STRUNK control system, among other things, so that the materials are joined with long-term stability and without aluminum spraying. This welding process for BUSBARS is also possible with CU strands or CU braid strands to make the conductor rail sets more flexible.

Aluminum stranded wire connections to (HV) round contacts – STRUNK HC-L process:

STRUNK CONNECT has developed a new process to reliably connect aluminum cables to round contacts using resistance welding.

- the metallic connection to the round contact (interior)

as well as - the metallic connection of the individual strands (cores) to each other

makes it possible. For this purpose, the cable lugs or round contacts are coated to avoid intermetallic phases and achieve long-term stability. Specially adapted resistance welding machines and the associated “ALUMINIUM” application software are now available from STRUNK Connect, which together enable a controllable and stable welding process between the strands and the necessary connection to the contact is achieved via a brazed joint of the respective coating.

This connection is also characterized by high holding forces and excellent conductivity from the aluminium cable to the copper contact. The breaking up of the oxides and the exact melting temperature of the strands is achieved by a special application of the STRUNK WELDING CURRENT CONTROL.

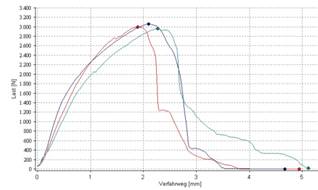

- Excellent conductivity of the Al-Cu compound

Fig. 2: Resistor 4.1µOhm stranded aluminum wire 50 mm²

It is now possible to combine the advantages of aluminum (weight saving, cost reduction compared to copper) with the known properties of copper in the contact area / connection area.