Resistance brazing and soldering

Resistance soldering – material connections with high connection cross-sections

With resistance brazing, divergent joining partners (in terms of geometry and material properties) and high connection cross-sections can be reliably connected. In general, brazing solder can be used in two forms:

- overlapping or in

- Butt welding process.

The butt-welded joint offers the following advantages:

- High savings in installation space (savings equal to the amount of the connector – max.height of the product corresponds to the strength of the terminal),

- strong reduction in compacting length (material savings),

- considerable reduction in the length of the contact part (material savings and advantages when punching),

- almost no heat input,

- almost no electrode wear,

- Tensile forces analogous to overlap welding or higher,

- very easy to monitor (analogous to overlapping welding),

- with the STRUNK process: no bulging at the joint (no reworking required),

- almost no contact resistance,

- all features of resistance welding are retained.

20 years of experience in resistance brazing

Process development with brazed welded joints has been part of the STRUNK portfolio for two decades. The starting point was an order from an OEM to develop an application with which oily stamped brass parts could be welded with a braid. The previously used connection methods led to a field failure and were therefore unusable.

Our consultig suggested that a resistor connection can be reliably mapped by adding a braze plate between the joining partners. In order to industrialize the feeding of the brazing alloy, we developed our first automated brazing alloy feeds for welding processes, which we have been continuously optimizing since then.

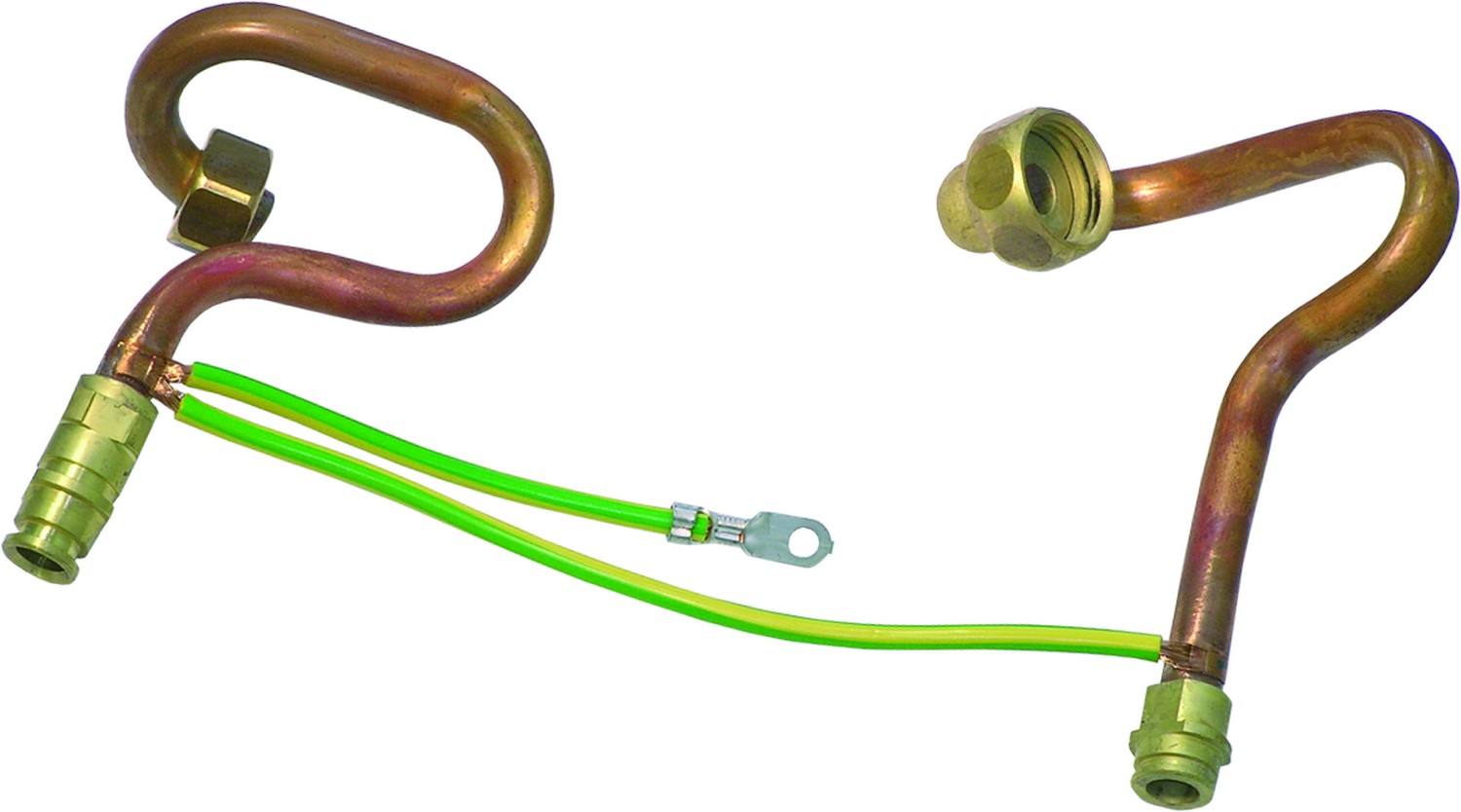

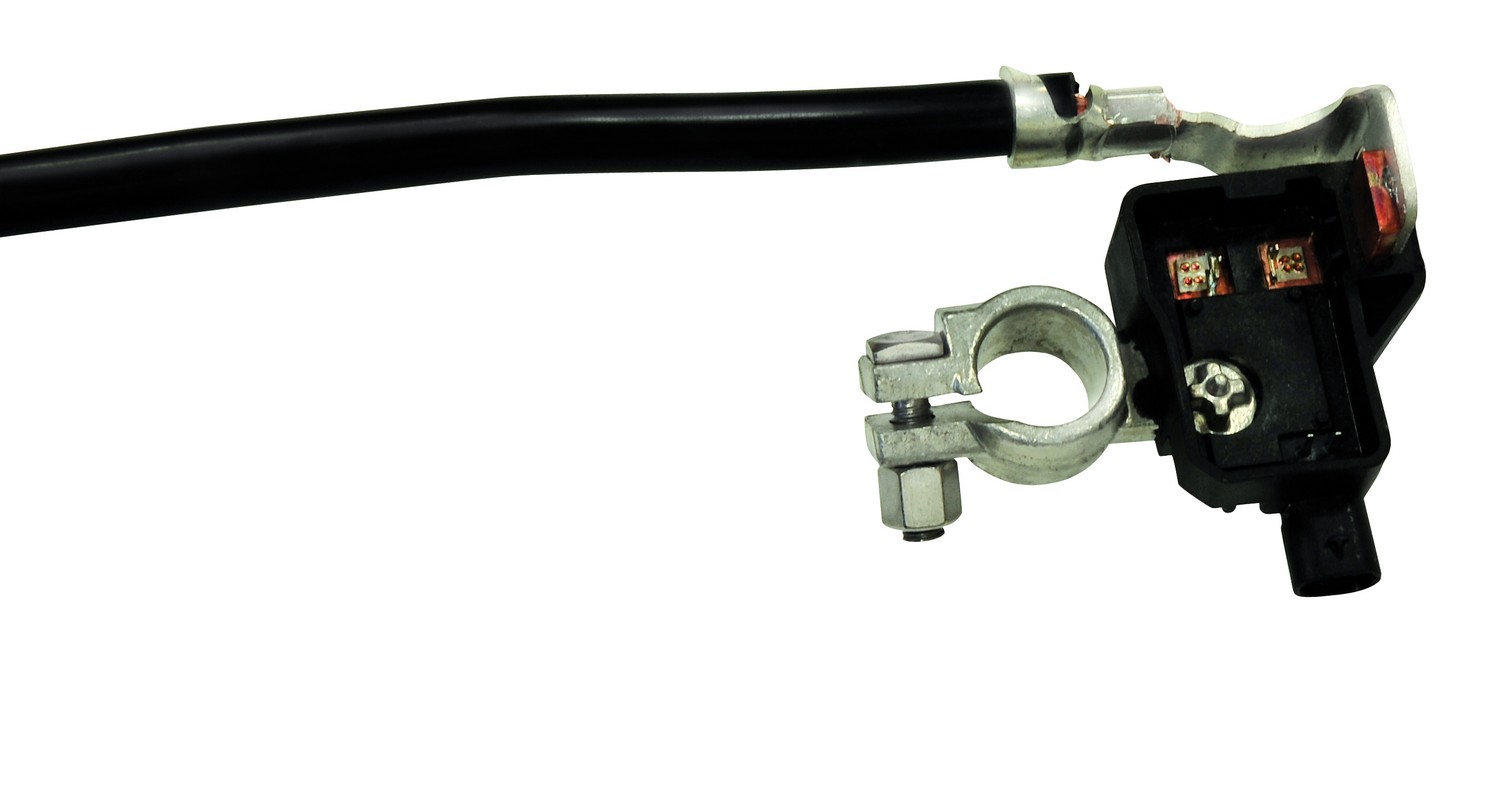

When the first intelligent battery sensors (IBS) appeared in the 12 V on-board network, the welding of the measuring shunt to the battery terminal, terminal or cable was already done with this process in manual to fully automatic production. Today almost all connections in the HV area (HV cabling and HV contacts), powertrain and power distribution (busbars and busbar electrical systems) are industrialized with this technology.

Resistance brazing is also useful if:

- the material thickness of the joining partners diverges so much that normal resistance welding cannot be carried out,

- the melting temperatures of the joining partners diverge significantly (e.g. copper to brass alloys),

- Large-area connections are to be implemented (BUS bars), where the connection by means of projection welding does not allow sufficient current carrying capacity to be achieved (connection only via projection -> HOT-SPOT = exclusion),

- Lines with large cross-sections are to be connected to terminals with extremely good conductivity (e.g. CuFe),

- the welding of the connection should be done with less machine power, ie concentration of the energy by the added solder, which increases the contact resistance before welding and then alloyed with both joining partners by melting.

In all cases mentioned, the resistance brazing results in an indestructible connection with a contact resistance of almost zero.

STRUNK Connect – your reliable partner for resistance welding under hard solder

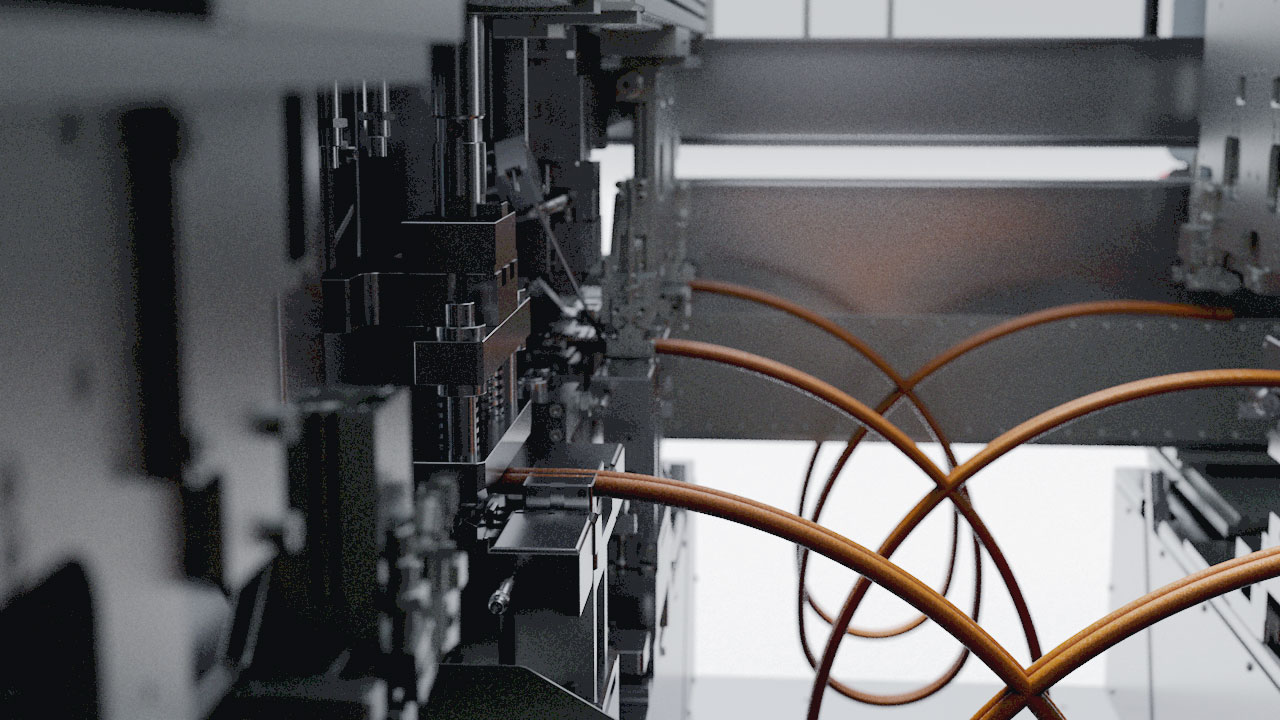

Our current integrated servo solder feeders deliver a precise and reproducible amount of solder using servo technology and a multi-roll principle. This ensures:

- an exact, precise and reproducible position of the solder between the joining partners,

- a straight line support even over long distances through shaping measures,

- an integrated monitoring of the applied amount of solder between the joining partners as a countercheck to the conveyed amount.

A punch cut to align the parameterization of the welding systems with the connection and not with the burning off of the solder.

Our control systems are fully integrated using independent software function modules, both in the welding current control and in the machine control. The feeds with a clamp system, which are suitable for right-hand and left-hand installation, sit on quick-change couplings with Harting plug connections, which enable a quick changeover to a different width. Flat materials with a cross-section of more than 0.05 mm² can be conveyed.

By supplying the hard solder, we achieve a current concentration at the desired point. By applying a short and strong welding current, the materials fuse to form a material bond that can only be separated in a destructive manner.

Our systems are not designed for pure soldering (melting of the brazing alloy) but, as with projection welding, are equipped with high power and high rigidity to produce the shortest possible welding time at very high welding currents.

In this way, we generate very high holding forces with the connection, whereby the contact resistance can be below the bulk resistance of the material (depending on the material). For example, with cables with a larger cross-section, pull-off forces of more than 10,000 Newtons can be achieved.

With this method, different materials with different cross-sections as well as BUS bars or busbars can be welded together. Contacts or busbars can also be provided with coatings.

We can use the method in the following variants. We are thus able to industrialize and automate a very high proportion of applications.

- Direct application of hard solder between the parts to be joined using semiautomatic and automatic machines : using automatic STRUNK conveyor technology as well as manual workstations with manual feeds:

-

- between two BUS bars / busbars / components,

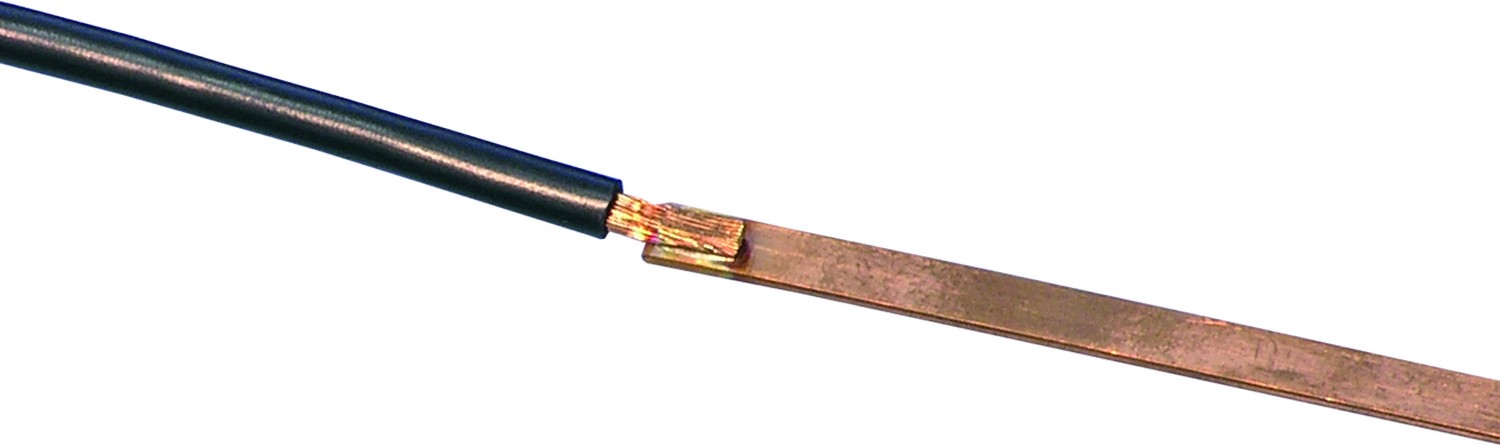

- between a compacted strand and a terminal or BUS bar,

- between an uncompacted stranded wire and a terminal or BUS bar (all-in-one shot)

-

- Pre-soldering of joining partners using automatic STRUNK conveyor technology as well as manual workstations with manual feeds:

-

- Pre-soldering of BUS bars / busbars,

- Pre-soldering during a compacting process (only possible semi or fully automatically due to the orientation (reference)). If the reference is lost, the orientation can be established manually in a second step using a marking).

-

With our practical solutions for resistance brazing, you can cope with the high technical requirements when joining workpieces and materials that are difficult to connect. Use our experience from more than 50 years of process technology to master your challenges in the area of resistance soldering and gain an edge over your competitors.

OVERLAP WELDING

(Individual customer solutions)

Cable to terminal connections

BusBar welding

Semi-automatic systems

Automatic systems

BUTT WELDING

(Individual customer solutions)

Manual production concepts

BELOTS

(Individual customer solutions)

Compacting under brazing & casting to terminal

Plumbing of power lines / BusBars / Terminals

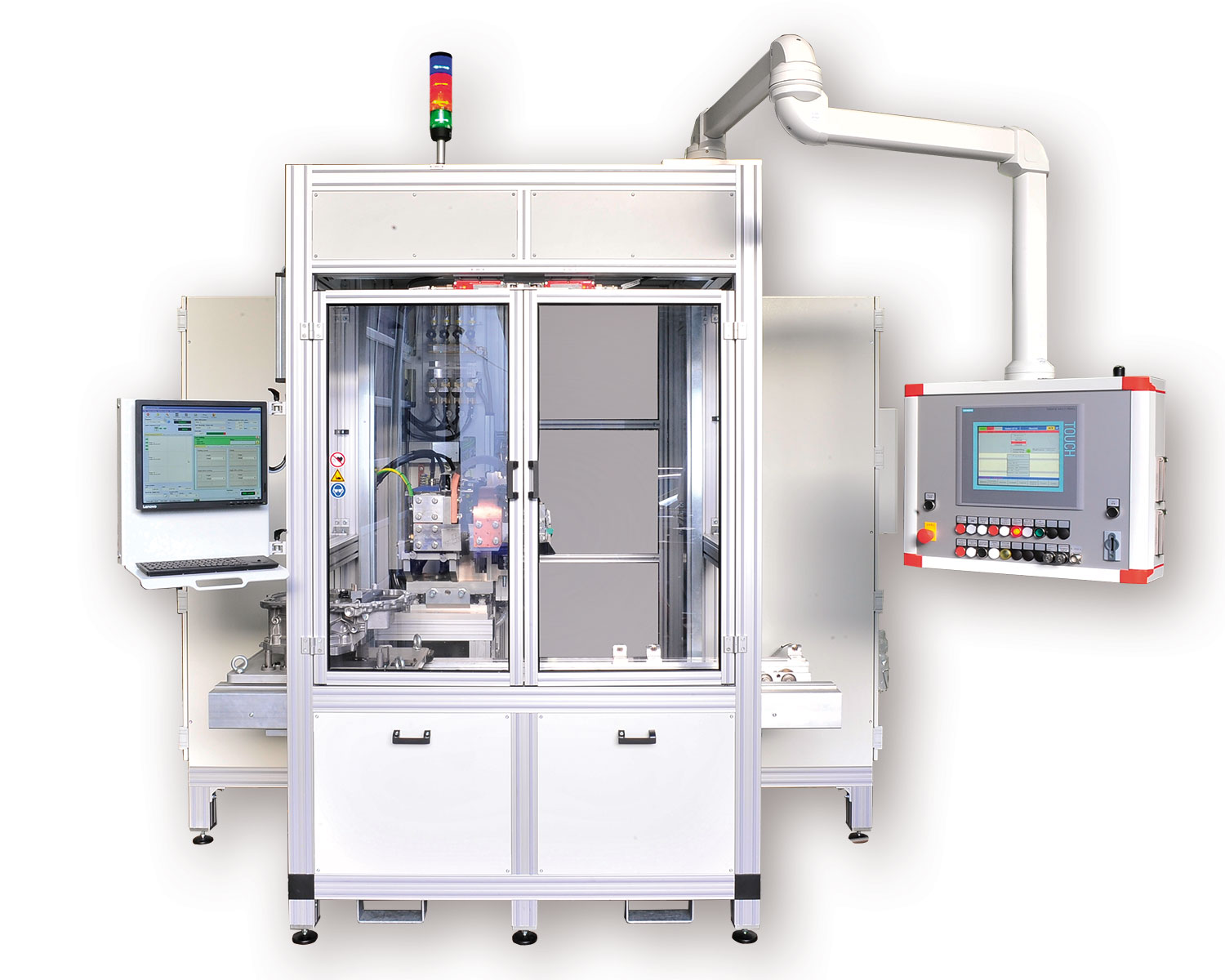

Automatic system with 4 servo-controlled axes and tool changing system for different products. The system includes a STRUNK 1,000 Hz medium frequency welding gun and the STRUNK SERVO brazing solder feeder for precise positioning of the solder pad on the BusBar.

Automatic machines for module connectors

Length transfer (individual customer solutions)

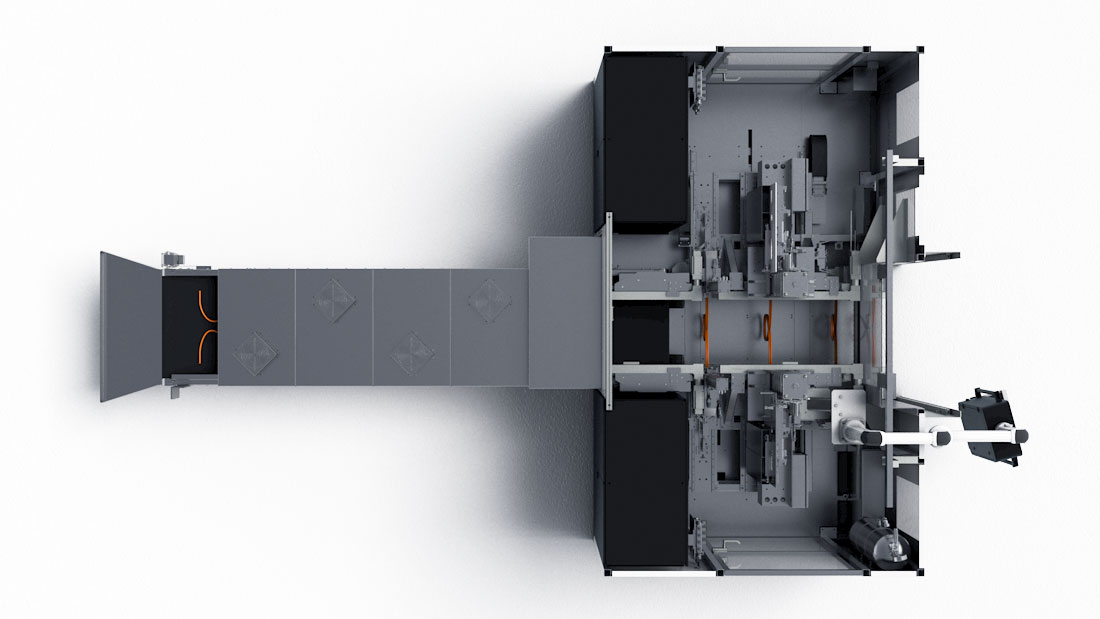

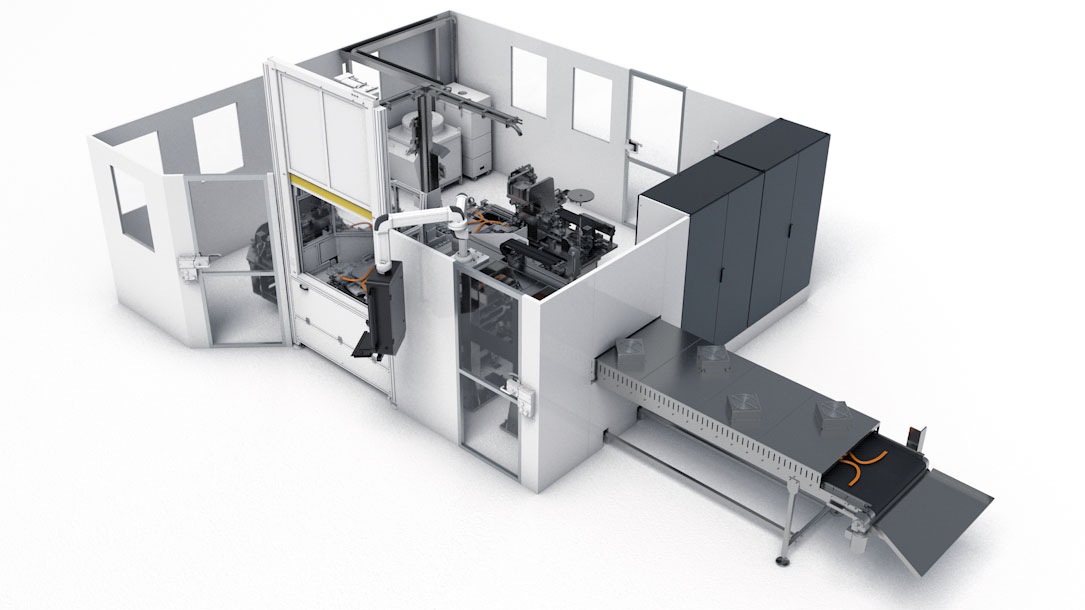

Transfer lines for compacting & punching as well as lap welding / butt welding Butt welding of braid strands and HV cable sets

Fully automatic transfer line for compacting and punching as well as overlap welding or butt welding of braid strands and HV cable harnesses STRUNK length transfer for module connectors, adjustable to cable lengths from 150mm to 2000mm. Single and double cables possible. STRUNK INTELLIGENT CLAMPING SYSTEM also allows different cable lengths to be mapped in the connector. The cable ends are processed simultaneously on both sides. Output is to a conveyor belt, sorted or unsorted depending on further processing and automation strategy. The systems are reinforced for large-area compacting and connecting surfaces.

Turntable systems (individual customer solutions)

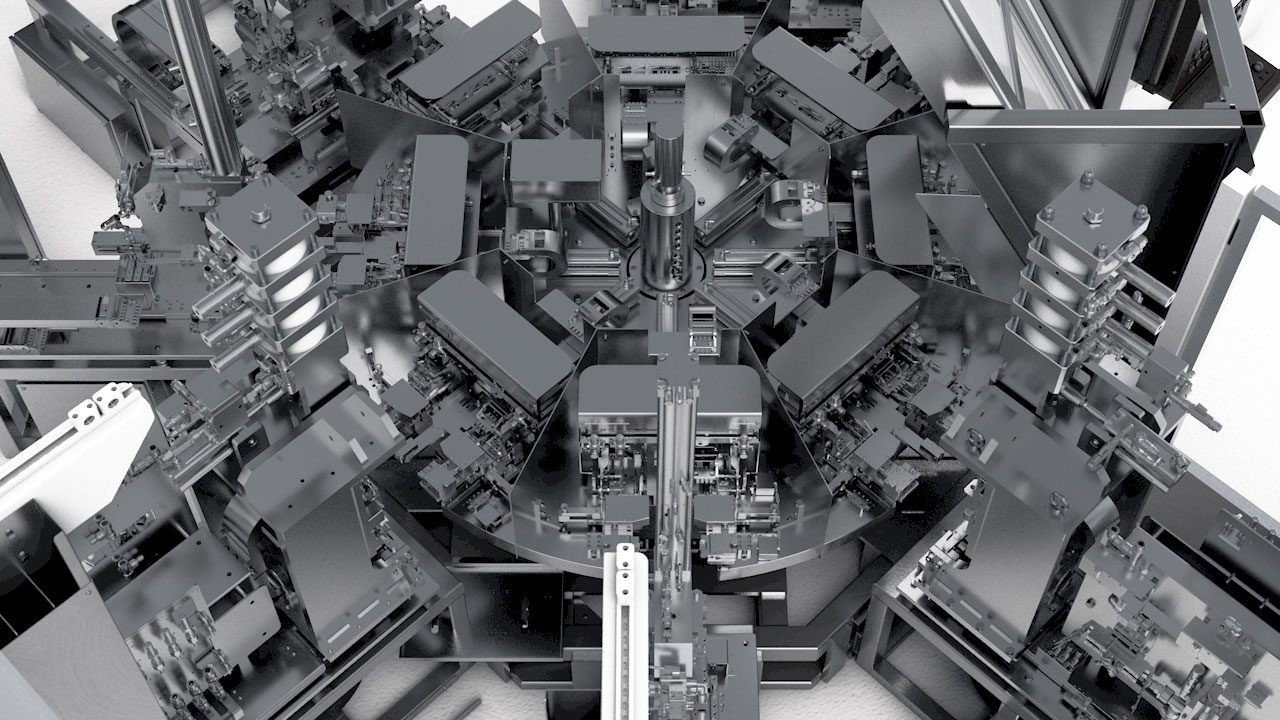

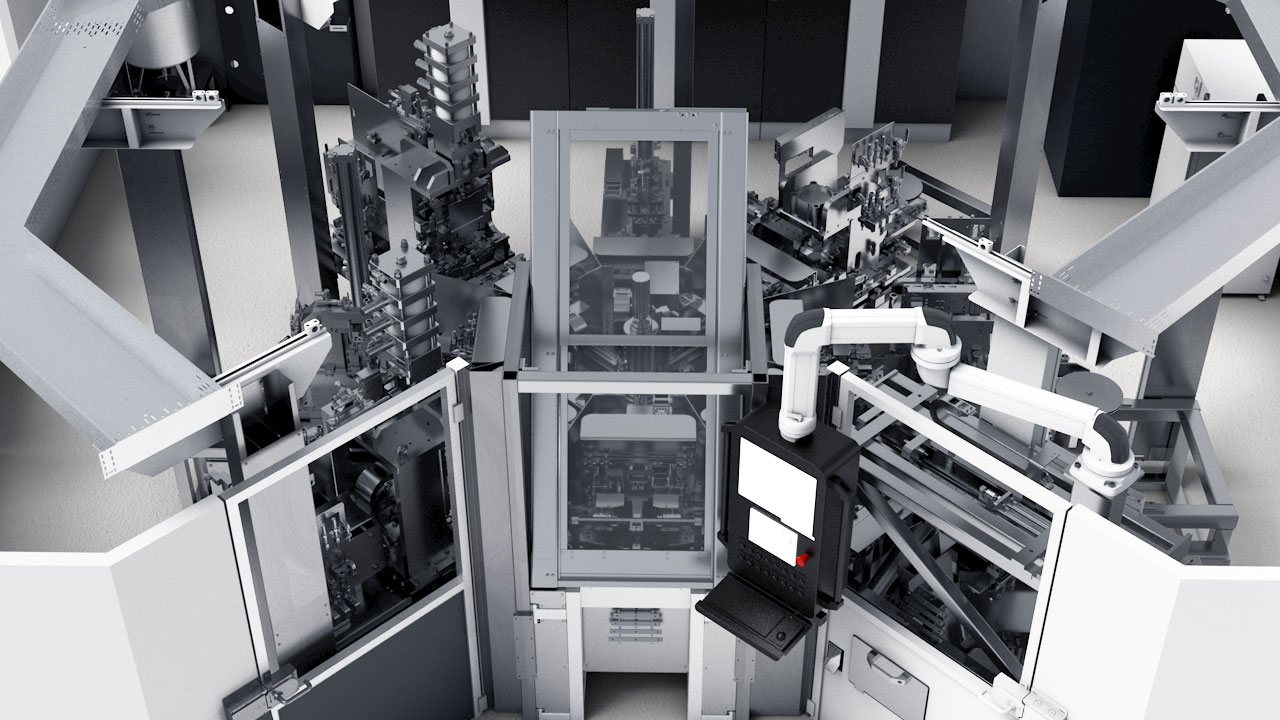

Systems for butt welding in turntable design for module connectors

Automatic systems for butt welding in turntable design for module connectors made of braided strands and HV cables. 18 variants are set up Poka Yoke and monitored. STRUNK automatic machine as a turntable solution for module connectors, adjustable to cable lengths from 150mm to 2000mm. Single and double cables possible. STRUNK INTELLIGENT CLAMPING SYSTEM also allows different cable lengths to be mapped in the connector. The cable ends are processed simultaneously on both sides. Output is to a conveyor belt, sorted or unsorted depending on further processing and automation strategy.

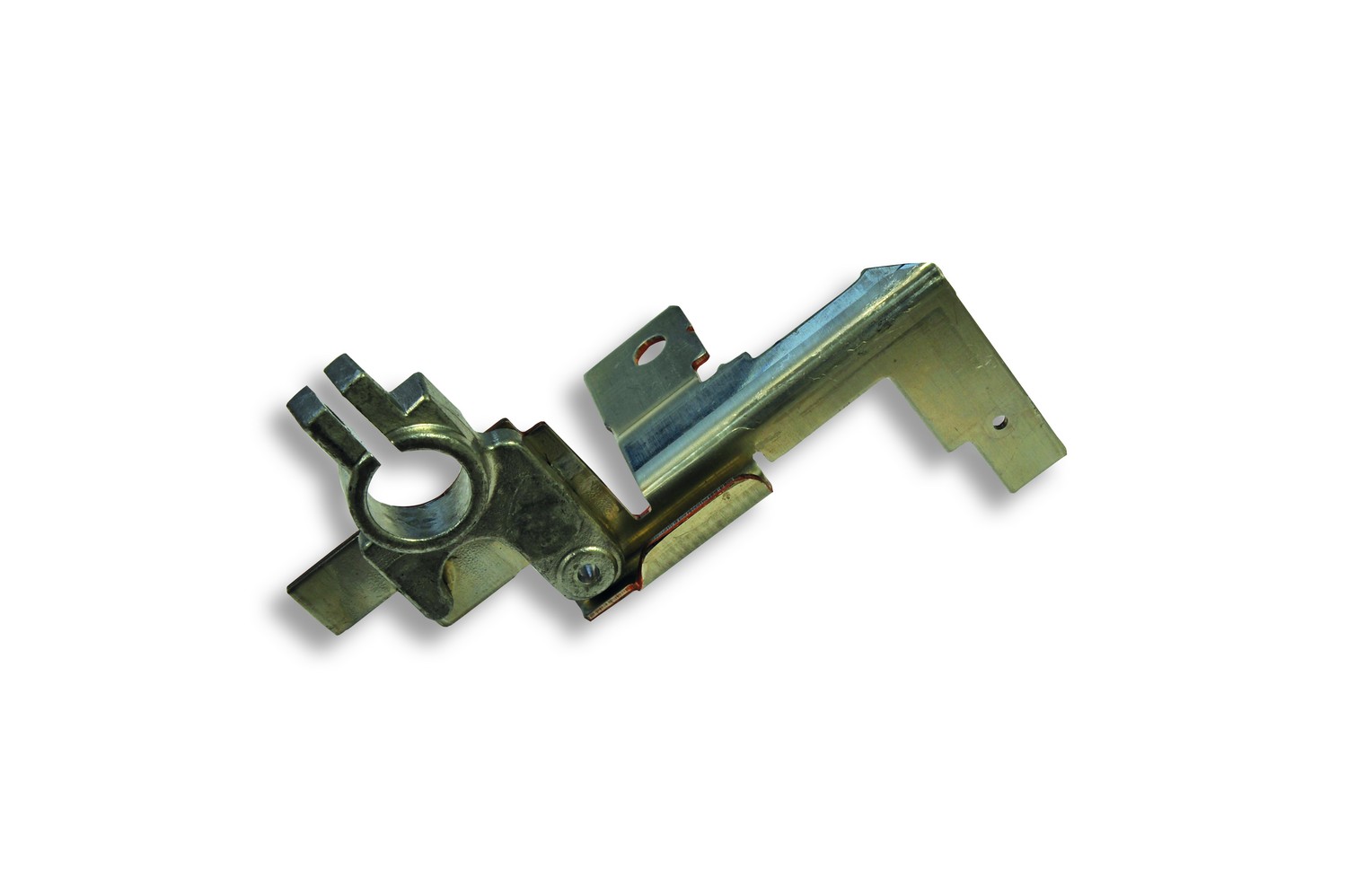

Sample

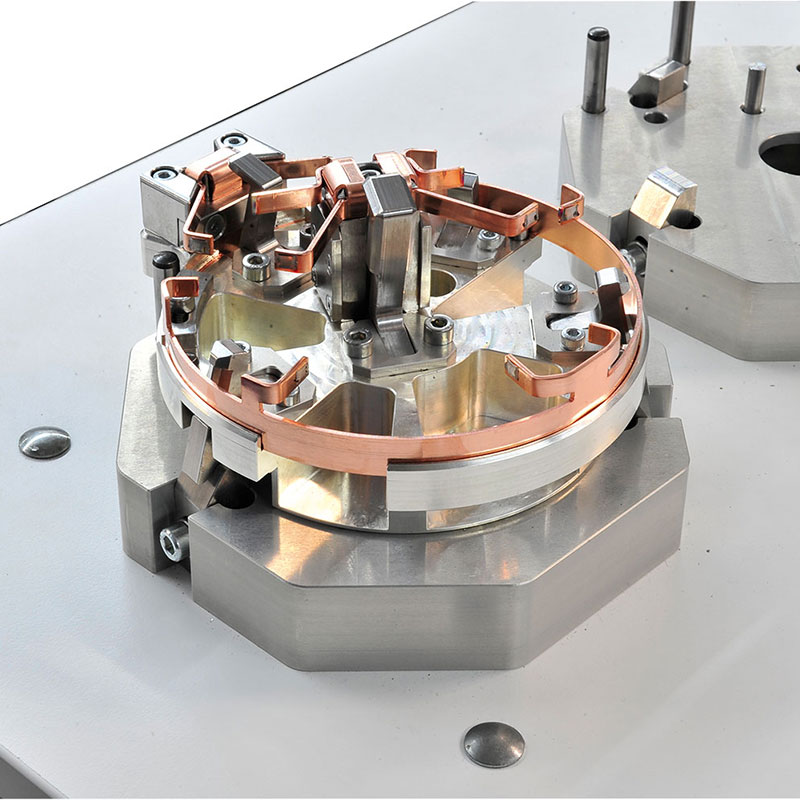

BusBar – Application in the field of power distribution for high voltage busbar wiring systems

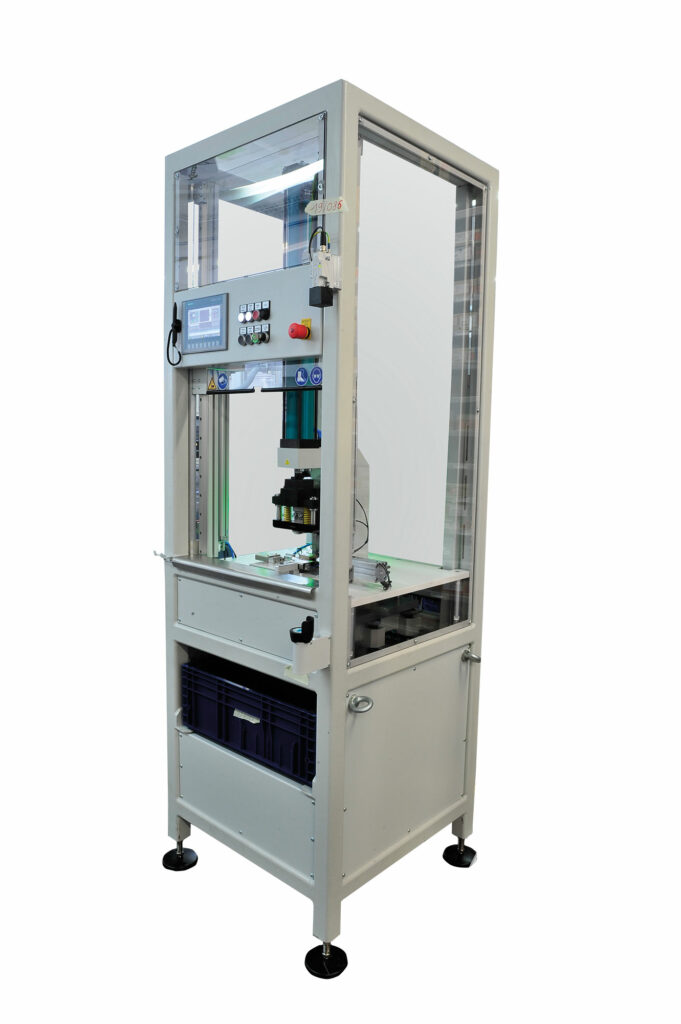

Flexible manual welding machine for connections under hard solder in the field of power distribution. Connections of BusBars to connection elements (HV contacts), BusBars to HV conductors and braid strands possible. The narrow design and the quick-change tools allow the production of busbars with difficult geometries. A flexible STRUNK servo brazing feeder with integrated monitoring can be connected at various angles on the right and left side. Furthermore, a 0° STRUNK SERVO brazing feed unit enables the feeding of different brazing widths through the welding unit. A conversion kit for compacting leads and braids up to 120mm2 is also available. he unit is capable of full traceablitly via camera or DMC. Connectable to STRUNK MES or customer side MES systems

BusBar – Applikation im Bereich der Power Distribution für Stromschienenbordnetze Hochvolt

Flexible manuelle Schweißanlage für Verbindungen unter Hartlot im Bereich Power Distribution. Verbindungen von BusBars zu Anschlusselementen (HV Kontakte), BusBars zu HV-Leitungen und Zopflitzen möglich. Das schmale Design und die schnell wechselbaren Werkzeuge ermöglichen die Fertigung von Stromschienen mit schwierigen Geometrien. Eine flexible STRUNK Servo Hartlotzufuhr mit integrierten Überwachungen kann unter verschiedensten Winkeln rechts- und linksseitig angeschlossen werden. Desweiteren ermöglicht eine 0° STRUNK SERVO Hartlotzuführeinheit die Zufuhr unterschiedlicher Lotbreiten durch die Schweißeinheit. Ein Umbausatz zum Kompaktieren von Leitungen und Zopflitzen bis 120mm2 ist zudem erhältlich. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme

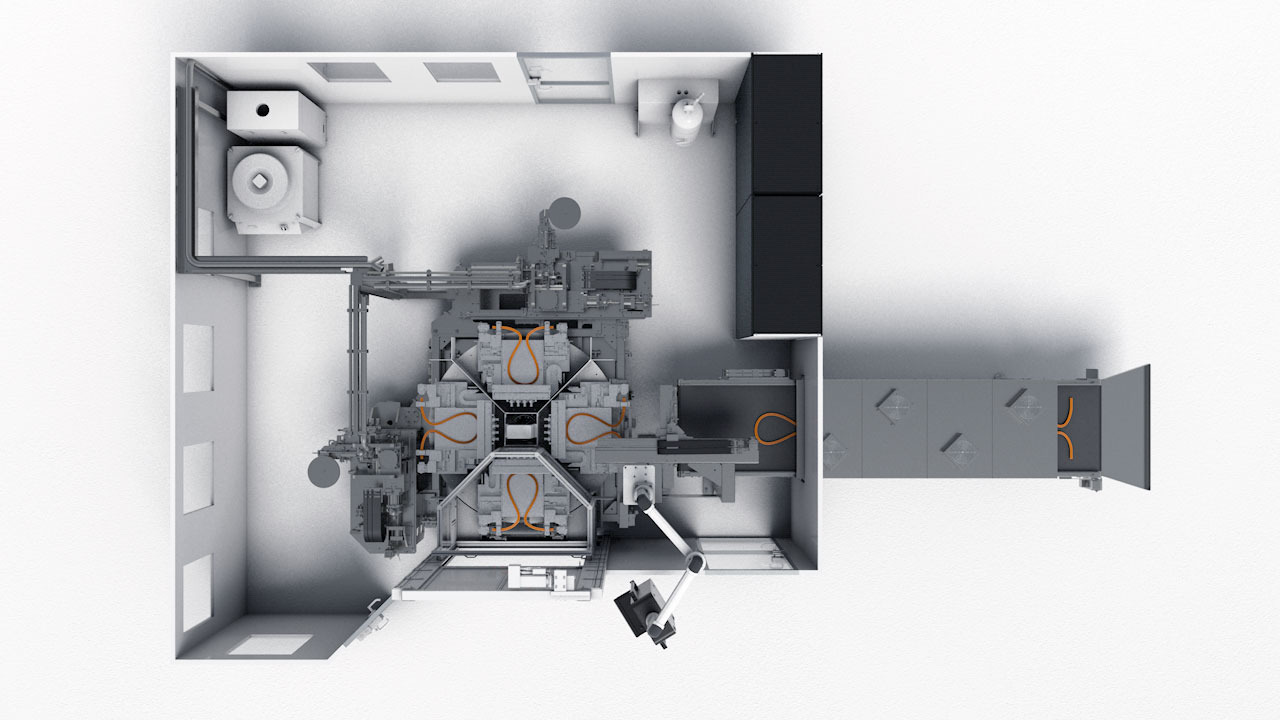

BusBars im Spritzguss – Applikation im Bereich der Leistungsverteilung (Power Distribution). Großflächige Anbindungen zwischen Kontaktteil und Stromschiene

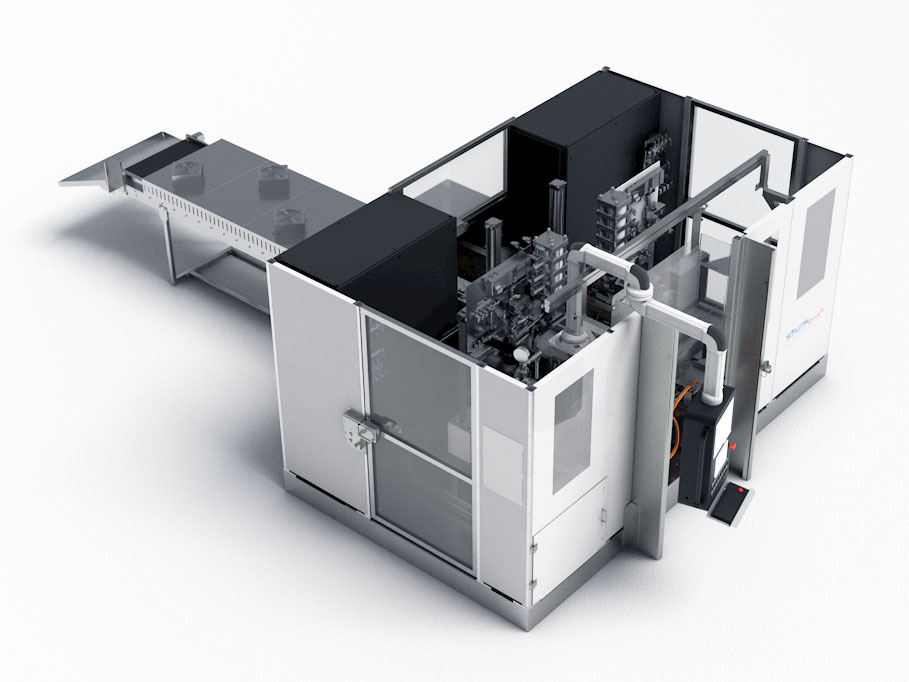

Sonderanlage als Vollautomat für Stromverteiler (BUSBARS) zu Kontakten. Die Handhabung der Bauteile und Positionierung erfolgt über Roboter in Deckenmontage. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme

STRUNK – Doppekopf – Transfer als Semiautomat für HV-Kontakte

Flexible semiautomatische Schweißzelle mit Transfer für das Kompaktieren unter Hartlot und Schweißen der Kompaktierten Leitung auf einen HV-Kontakt. Durch die Kompaktierung unter Hartlot und dem automatischen Übersetzen der Kompaktierten Leitung werden genaueste Maße und Reproduzierbarkeiten erreicht. Ein Rüstvorgang auf einen anderenHV-Kontakt ist schnellstens durch einfachen Tausch des Schweißnestes erledigt. Die Greifsysteme verfügen über NOK Cutter und die Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme. Einsatzbereich von 6-95mm2

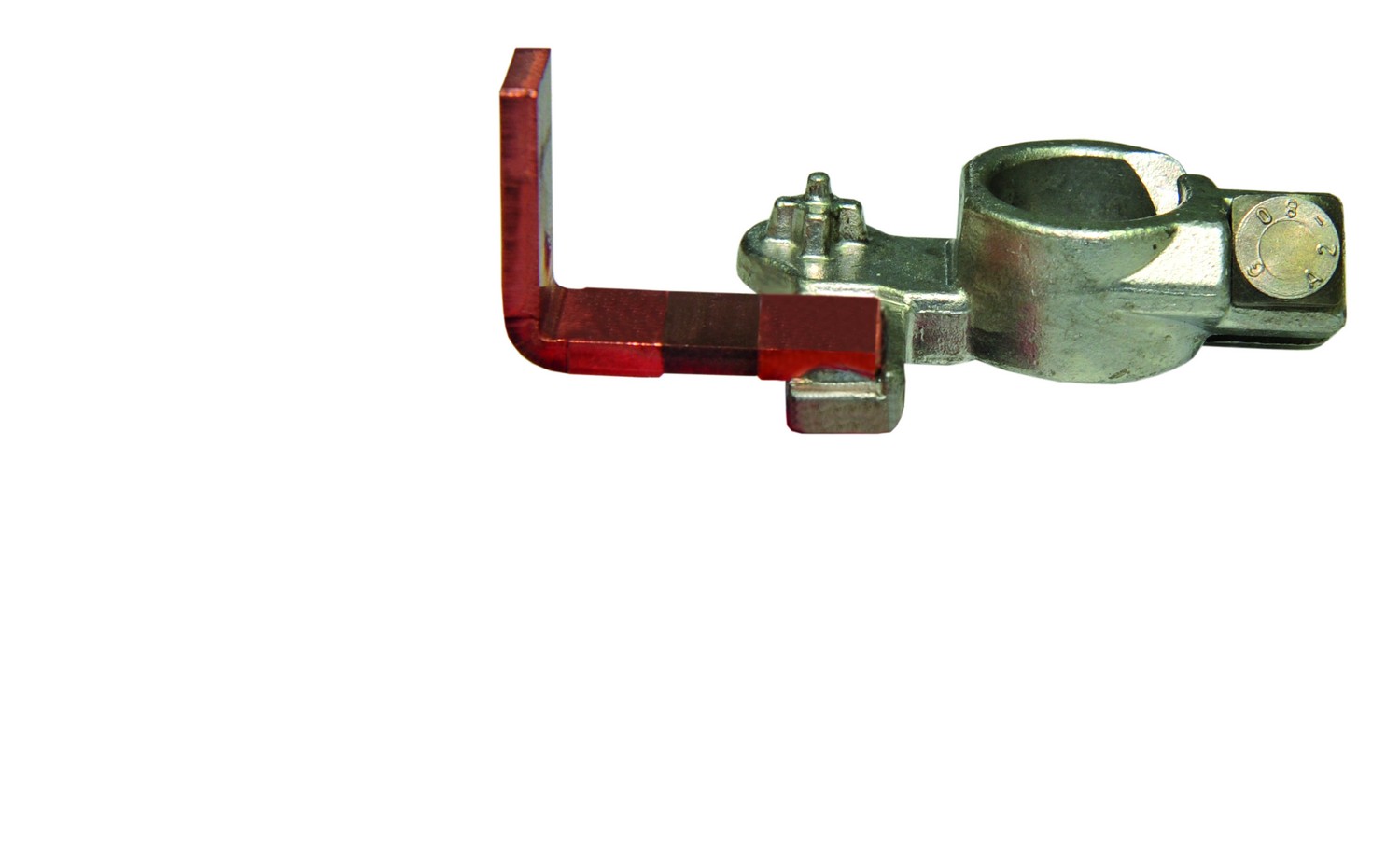

Schweißen von Batterieklemmen auf Cu Schienen. Applikation Sicherungsbox.

Automat mit Mehrfach STRUNK SERVO Hartlotzuführung und Servo – Portalen, ausgerüstet mit 150 KVA STRUNK Schweißzange für die Mehrfachschweißung unter Hartlot an einem Bauteil

Schweißen von Batterieklemmen auf Cu Schienen. Applikation Sicherungsbox.

Automat mit Mehrfach STRUNK SERVO Hartlotzuführung und Servo – Portalen, ausgerüstet mit 150 KVA STRUNK Schweißzange für die Mehrfachschweißung unter Hartlot an einem Bauteil

STRUNK – Doppekopf – Transfer als Semiautomat für Kompaktieren unter Hartlot und Aufschweißen auf Rohre

Flexible semiautomatische Schweißzelle mit Transfer für das Kompaktieren unter Hartlot und Schweißen der Kompaktierten Leitung auf einen HV-Kontakt. Durch die Kompaktierung unter Hartlot und dem automatischen Übersetzen der Kompaktierten Leitung wir die Schweißung auf das Rohr ermöglicht, ohne dieses zu deformieren.

Cu Leitung zu Stromschiene geschweißt unter Hartlot als ALL IN ONE SHOT Lösung

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr für die ALL IN ONE SHOT Lösung, d.h. Kompaktierschweißen unter Hartlot in einem Zug. Die Leitung wird unter Zufuhr von Hartlot (STRUNK automatische SERVO Zuführung) auf den Kontakt kompaktiert und geschweißt.

Schweißen unter Hartlot von Kabeln oder BusBars zu intelligenten Batteriesensoren (IBS)

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr aufgebaut auf Schnellwechselkupplungen. Werkzeuge auf Schnellwechselplatten für den raschen Umbau auf eine andere Applikation. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Für Kabellösungen auch als ALL IN ONE SHOT Lösung möglich

Überlappende Schweißung von Zopflitze zu BusBar und Belotung einer Kompaktierung (Kompaktieren unter Hartlot)

Flexible semiautomatische Schweißzelle mit Transfer für das Kompaktieren unter Hartlot und Schweißen der Kompaktierten Leitung auf einen HV-Kontakt. Durch die Kompaktierung unter Hartlot und dem automatischen Übersetzen der Kompaktierten Leitung werden genaueste Maße und Reproduzierbarkeiten erreicht. Ein Rüstvorgang auf einen anderenHV-Kontakt ist schnellstens durch einfachen Tausch des Schweißnestes erledigt. Die Greifsysteme verfügen über NOK Cutter und die Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme. Einsatzbereich von 6-95mm2

Schweißen unter Hartlot von Kabeln oder BusBars zu intelligenten Batteriesensoren (IBS)

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr aufgebaut auf Schnellwechselkupplungen. Werkzeuge auf Schnellwechselplatten für den raschen Umbau auf eine andere Applikation. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Für Kabellösungen auch als ALL IN ONE SHOT Lösung möglich

Schweißen unter Hartlot (Widerstandshartlöten) von Phasenanschlüssen am Klemmbrett.

Vollautomatische Zangenschweißanlage 150KVA mit Transferband für das Schweißen unter Hartlot Phasenanschlüssen.

Schweißen unter Hartlot (Widerstandshartlöten) von Phasenanschlüssen am Klemmbrett.

Vollautomatische Zangenschweißanlage 150KVA mit Transferband für das Schweißen unter Hartlot Phasenanschlüssen.

BusBars im Spritzguss – Applikation im Bereich der Leistungsverteilung (Power Distribution). Großflächige Anbindungen zwischen Kontaktteil und Stromschiene

Sonderanlage als Vollautomat für Stromverteiler (BUSBARS) zu Kontakten. Die Handhabung der Bauteile und Positionierung erfolgt über Roboter in Deckenmontage. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme

Schweißen unter Hartlot (Widerstandshartlöten) von Stromschienen und Spulen (Induktivitäten)

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr aufgebaut auf Schnellwechselkupplungen. Werkzeuge auf Schnellwechselplatten für den raschen Umbau auf eine andere Applikation. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig.

Schweißen unter Hartlot von Kabeln oder BusBars zu intelligenten Batteriesensoren (IBS)

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr aufgebaut auf Schnellwechselkupplungen. Werkzeuge auf Schnellwechselplatten für den raschen Umbau auf eine andere Applikation. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Für Kabellösungen auch als ALL IN ONE SHOT Lösung möglich

Schweißen unter Hartlot (Widerstandshartlöten) von Stromschienen und BusBars

Manuelle Schweißzelle mit automatischer STRUNK SERVO Hartlotzufuhr aufgebaut auf Schnellwechselkupplungen. Werkzeuge auf Schnellwechselplatten für den raschen Umbau auf eine andere Applikation. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig.

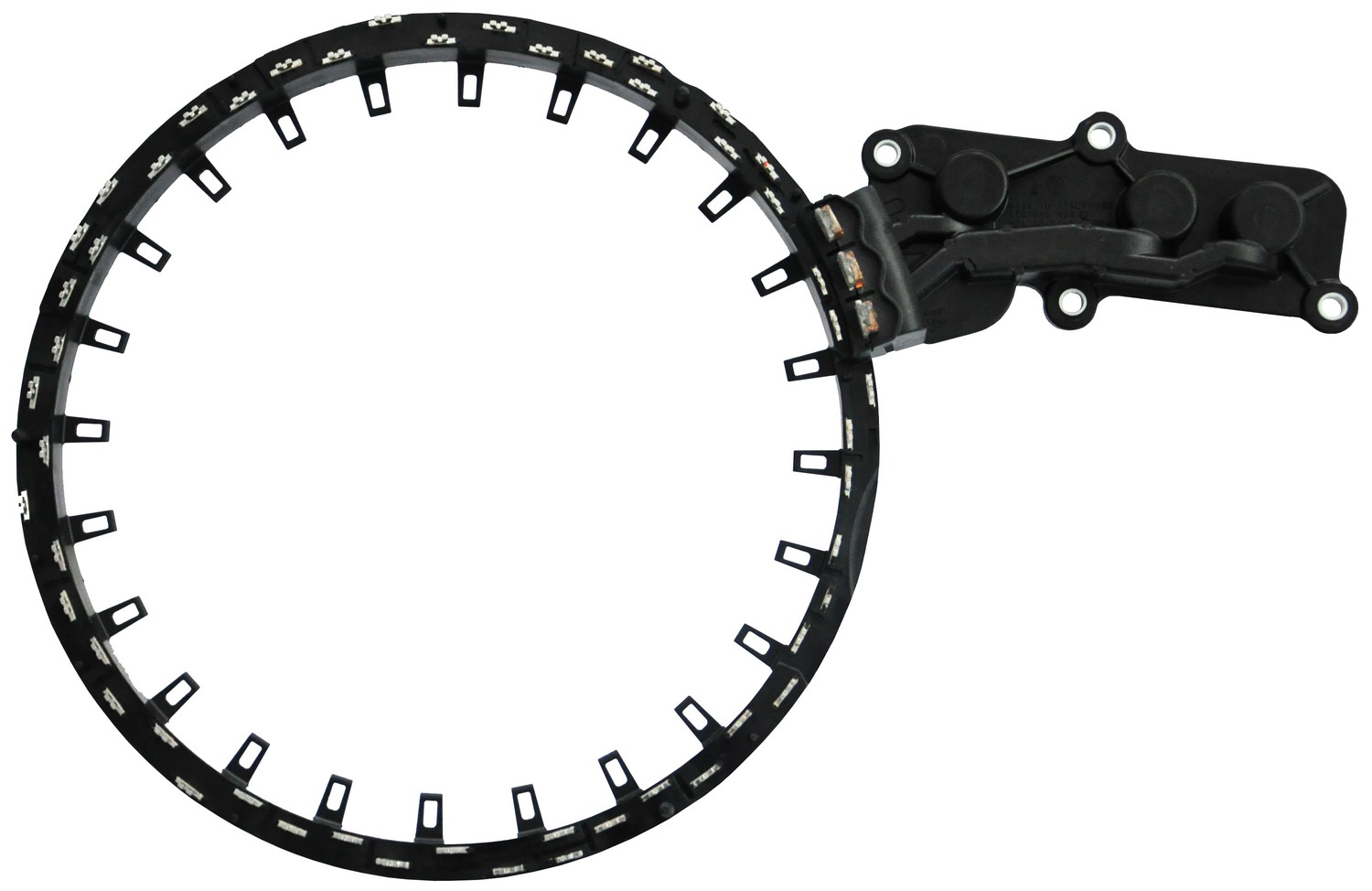

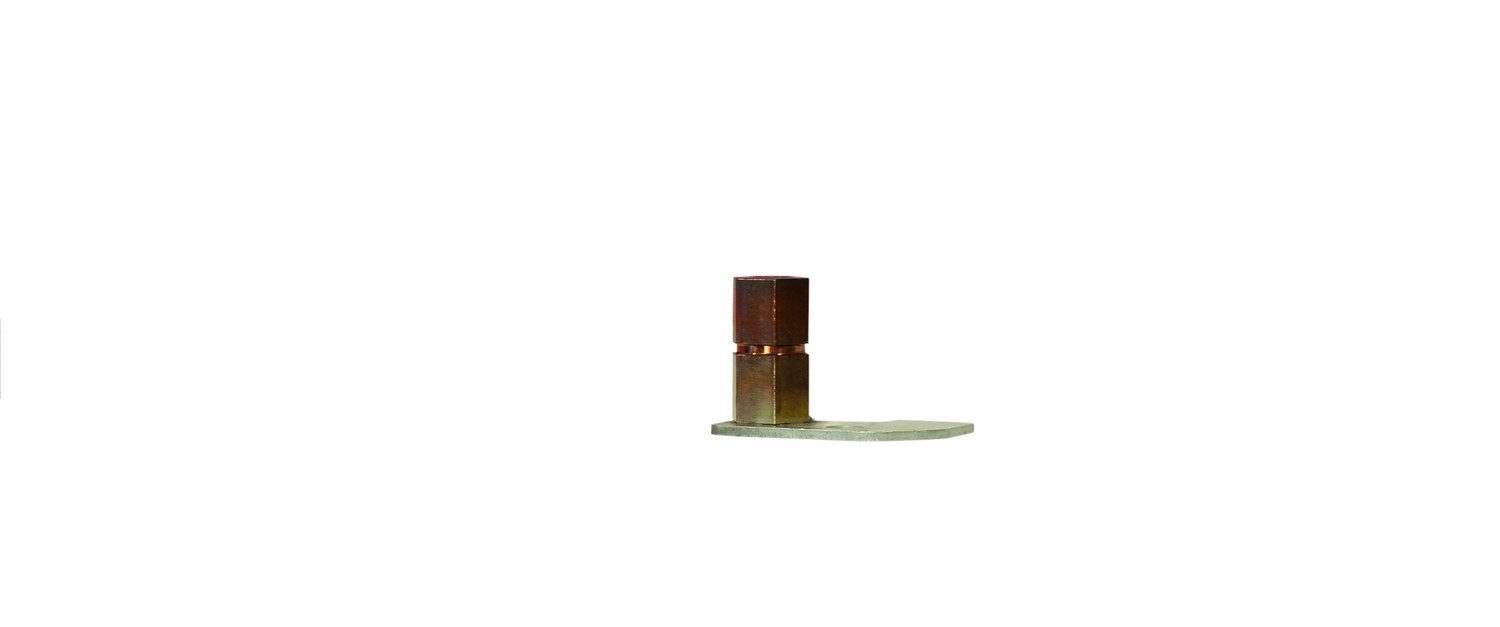

Ring oder Bolzenschweißen unter Hartlot

Manuelle Anlage für das Schweißen unter Hartolot von Cu-Ringen oder Bolzen als Anschlusselement zu BusBars oder Kabel. Anlagen auch automatisiert darstellbar im STRUNK TRANSFER oder als STRUNK DREHTISCHLÖSUNG

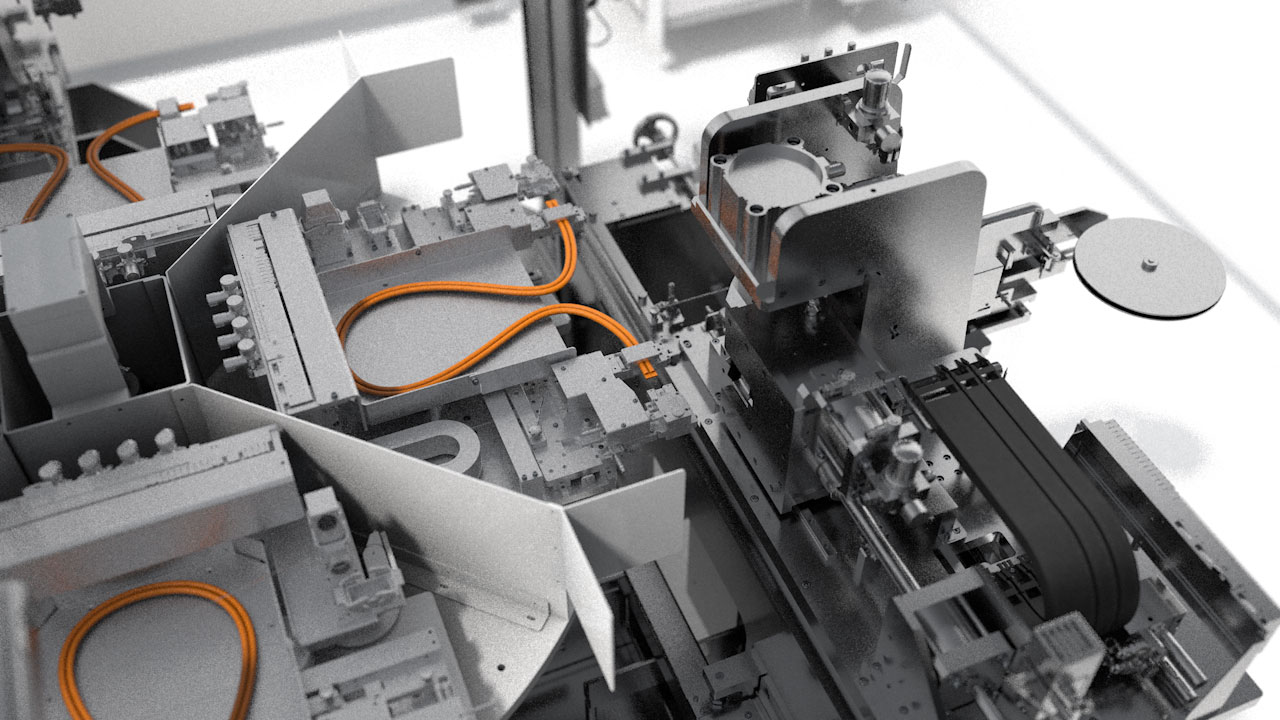

Belotung von Stromschienen

Automatische Anlage mit 4 servo gesteuertern Achsen sowie Werkzeug-Wechselsystem für unterschiedliche Produkte. Die Anlage enthält eine STRUNK 1.000HZ Mittelfrequenz – Schweißzange sowie die STRUNK SERVO Hartlotzufuhr für die genaue Postionierung des Lot – Pads auf dem BusBar.

BusBar-Applikation im Bereich der Battery (Power Distribution)

Flexible manuelle Schweißanlage für Verbindungen unter Hartlot im Bereich Power Distribution. Verbindungen von BusBars zu Anschlusselementen (HV Kontakte), BusBars zu HV-Leitungen und Zopflitzen möglich. Das schmale Design und die schnell wechselbaren Werkzeuge ermöglichen die Fertigung von Stromschienen mit schwierigen Geometrien. Eine flexible STRUNK Servo Hartlotzufuhr mit integrierten Überwachungen kann unter verschiedensten Winkeln rechts- und linksseitig angeschlossen werden. Desweiteren ermöglicht eine 0° STRUNK SERVO Hartlotzuführeinheit die Zufuhr unterschiedlicher Lotbreiten durch die Schweißeinheit. Ein Umbausatz zum Kompaktieren von Leitungen und Zopflitzen bis 120mm2 ist zudem erhältlich. ie Anlage ist über Kamera oder DMC für die vollständige Traceablitly fähig. Anschließbar an STRUNK MES oder kundenseite MES Systeme